Forged 90° Socket weld Elbow Manufacturers in India

Forged 90° Socket weld Elbow manufacturer, Forged 90° Socket weld Elbow, 90° Socket weld Elbow, Forged Socket weld Elbow Manufacturers in India ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 Forged 90° Socket weld Elbow

Forged 90° Socket weld Elbow manufacturers, Forged 90° Socket weld Elbow, Forged 90° Socket weld Elbow suppliers, Socket Weld Seamless/Seam Welded Forged Fittings, Socket Weld Fabricated Forged Fittings, Forged 90° Socket weld Elbow Suppliers in Indonesia, UAE, Saudi Arabia, Oman, Qatar, Australia.

Riton Metal Industries is specialized in manufacturing and supplying of Forged 90° Socket weld Elbow , Pipe Fitting, Forged Fittings, Butt weld fittings in Stainless steel, alloy Steel & carbon Steel since 1991, we manufacture wide range of Forged 90° Socket weld Elbow such as Socket Weld Elbows, Socket Weld Tees, Socket Weld Reducers, Socket Weld pipe end Caps, Socket Weld Pipe Bends etc. as per International standard like ASME/ASTM/API, we are supplying & exporting Forged 90° Socket weld Elbow in seamless & welded both forms to more than 60 countries for over 2 decades, we have our dealers & distributors in Nigeria, Australia, Malaysia, Egypt, South Africa, Tanzania, Kenya, Mozambique, Angola, Gabon Germany, Turkey, France, United Kingdom, Italy, Netherlands, Iran , Iraq , Saudi Arabia, United Arab Emirates , Iisrael, Jordan, Oman, Kuwait, Qatar, Bahrain, Bangladesh, China, Indonesia, South Korea, Pakistan, Philippines, Singapore, Sri Lanka, Thailand, Vietnam, Brazil, Colombia, Argentina & United States of America, Riton Metal Industries is the only company in INDIA which is approved Manufacturer & supplier of Forged 90° Socket weld Elbow in 300 top companies worldwide. Few of them are ORPIC, NIORDC, Saudi Aramco, SABIC, PIDMCO, GASCO, KNPC, Indian Oil, BPCL, HPCL, NTPC, BARC & Indian Navy, Riton Metal Industries is ISO 9001:2008, ISO 14001, OHSAS 18001 Certified Company since 2006 & PED approved Manufacturer since 2008, Riton Metal Industries is India's 6th largest Manufacturer, supplier & exporter of Forged 90° Socket weld Elbow .

Infrastructure :

Riton Metal Industries is 6th largest Forged 90° Socket weld Elbow & Flanges manufacturers in INDIA. we have following latest automated machines to manufacture Forged 90° Socket weld Elbow : Induction Elbow Making Machines, Bulge Forming Machine, Pipe Bending Machine, Elbow Cold Forming Machine, Induction Elbow Machine, Hydraulic Pressing Machine, Elbow and Pipe Bending Machine, Beveling Machine, we have largest Four-Column Hydraulic Press in INDIA which is used for pipe bending, pipe fitting press forming, metal sheet stretching and pulling. Now Riton Metal Industries . is INDIA's largest Engineering & Forging Company related to Petro-Chemical and Oil & Gas Industry.

Materials and Grade :

| Specification | : | ASTM A182, ASTM SA182 |

| Dimension | : | ANSI B 16.11 |

| Size | : | 1/4" NB TO 4" NB |

| Class | : | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Range | : | Coupling, Plug, Socket, Bushing, Elbow, Tee, Nipple, Union,Threading Outlet, Welding Outlet, Sockt Weld Outlet. |

| Stainless Steel Socket Weld 90° Forged Elbow | : | ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Duplex Steel Socket Weld 90° Forged Elbow | : | ASTM A 182 –F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 S 31803, S 32205, S 32550, S 32750, S 32760 |

| Carbon Steel Socket Weld 90° Forged Elbow | : | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2 |

| Alloy Steel Socket Weld 90° Forged Elbow | : | ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91. |

| Copper Alloys Socket Weld 90° Forged Elbow | : | ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500 ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) |

| Nickel Alloy Socket Weld 90° Forged Elbow | : | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

Forged 90 Deg Socket Weld Elbow Material Size & Specification :

| Specification |

|

|---|---|

| Forged 90 Deg Socket Weld Elbow Dimension | ANSI B 16.11 |

| Forged 90 Deg Socket Weld Elbow Size | 1/4" NB TO 4" NB |

| Forged 90 Deg Socket Weld Elbow Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Forged steel fittings Range | Coupling, Plug, Socket, Bushing, Elbow, Tee, Nipple, Union,Threading Outlet, Welding Outlet, Sockt Weld Outlet. |

| Stainless Steel Forged 90 Deg Socket Weld Elbow | ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Duplex Steel Forged 90 Deg Socket Weld Elbow | ASTM A 182 –F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 S 31803, S 32205, S 32550, S 32750, S 32760 |

| Carbon Steel Forged 90 Deg Socket Weld Elbow | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2 |

| Alloy Steel Forged 90 Deg Socket Weld Elbow | ASTM / ASME A 182 GR F5, F 9, F 11, F 12, F 22, F 91. |

| Copper Alloys Forged 90 Deg Socket Weld Elbow | ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500 ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10) , C 71500 (CU -NI- 70/30) |

| Nickel Alloy Forged 90 Deg Socket Weld Elbow | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB 3), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

| Low temperature steel: | A522 A707 Grade L 1-L 2-L 3-L 4-L 5-L 6-L 7-L 8 |

| High performance steel: | A694 F 42-F 46-F 48-F 50-F 52-F 56-F 60-F 65-F 70 |

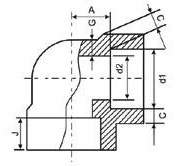

Forged 90° Socket Weld Elbow Dimensions :

| Nominal Diameter | Depth of Socket | Dimension of Socket | Wall Thickness | Center to Bottom of Socket | ||||||||

| A | ||||||||||||

| Cmin | 90°Elbow | |||||||||||

| DN | NPS | Jmin | d1 | 3000LB Sch80 | 6000LB Sch160 | 9000LB XXS | 3000LB Sch80 | 6000LB Sch160 | 9000LB XXS | |||

| 6 | 1/8 | 10 | 10.7 | 3.2 | 3.5 | - | 11 | 11 | - | |||

| 8 | 1/4 | 10 | 14.1 | 3.3 | 4.0 | - | 11 | 15 | - | |||

| 10 | 3/8 | 10 | 17.5 | 3.5 | 4.4 | - | 13 | 15 | - | |||

| 15 | 1/2 | 10 | 21.8 | 4.1 | 5.2 | 8.2 | 16 | 19 | 25 | |||

| 20 | 3/4 | 13 | 27.4 | 4.3 | 6.1 | 8.6 | 19 | 22 | 28 | |||

| 25 | 1 | 13 | 34.2 | 5.0 | 7.0 | 10.0 | 22 | 27 | 32 | |||

| 32 | 1.1/4 | 13 | 42.9 | 5.3 | 7.0 | 10.6 | 27 | 32 | 35 | |||

| 40 | 1.1/2 | 13 | 48.3 | 5.6 | 7.8 | 11.2 | 32 | 38 | 38 | |||

| 50 | 2 | 13 | 61.1 | 6.1 | 9.5 | 12.2 | 38 | 41 | 41 | |||

| 65 | 2.1/2 | 16 | 76.9(73.8) | 7.7 | 12.5 | - | 41 | 57 | - | |||

| 80 | 3 | 16 | 89.8 | 8.3 | 13.8 | - | 57 | 64 | - | |||

| 100 | 4 | 19 | 115.5 | 9.4 | - | - | 66 | - | - | |||

Socket Weld Elbows – NPS 1/2 to 4 – 90° – 3000 LBS – ASME B16.11 :

| NPS | Socket Bore |

Depth Socket |

Bore diameter |

Socket wall thickness |

Body wall thickness |

Center to bottom of socket A |

|

|---|---|---|---|---|---|---|---|

| B | J | D | C | G | 90° | 45° | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 | 3.75 | 15.5 | 11.5 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 | 3.90 | 19.5 | 12.5 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 | 4.55 | 22 | 14 |

| 1¼ | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 | 4.85 | 27 | 17 |

| 1½ | 48.90 48.65 | 13 | 41.7 40.1 | 6.35 5.55 | 5.10 | 32 | 21 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6.95 6.05 | 5.55 | 38 | 25 |

| 2½ | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 | 7.00 | 41.5 | 29 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 | 7.60 | 57.5 | 31.5 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 | 8.55 | 66.5 | 41.5 |

Socket Weld Elbows – NPS 1/2 to 2 – 90° – 6000 LBS – ASME B16.11 :

| NPS | Socket Bore |

Depth Socket |

Bore diameter |

Socket wall thickness |

Body wall thickness |

Center to bottom of socket A |

|

|---|---|---|---|---|---|---|---|

| B | J | D | C | G | 90° | 45° | |

| 1/2 | 21.95 21.70 | 10 | 12.5 11 | 5.95 5.20 | 4.80 | 19.5 | 12.5 |

| 3/4 | 27.30 27.05 | 13 | 16.3 14.8 | 6.95 6.05 | 5.55 | 22.5 | 14.5 |

| 1 | 34.05 33.80 | 13 | 21.5 19.9 | 7.90 6.95 | 6.35 | 27 | 17 |

| 1¼ | 42.80 42.55 | 13 | 30.2 28.7 | 7.90 6.95 | 6.35 | 32 | 21 |

| 1½ | 48.90 48.65 | 13 | 34.7 33.2 | 8.90 7.80 | 7.15 | 38 | 25 |

| 2 | 61.35 61.10 | 16 | 43.6 42.1 | 10.90 9.50 | 8.75 | 41 | 29 |

- Dimensions are in millimeters unless otherwise indicated.

- Socket Bore (B) – Maximum and minimum dimensions.

- Bore Diameter (D) – Maximum and minimum dimensions.

- Socket wall thickness – (C) – Average of Socket wall thickness.

- Dimensional tolerances center to bottom of socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2½ to NPS 4 = +/- 2.5 mm

- Dimensions are in millimeters unless otherwise indicated.

- Socket Bore (B) – Maximum and minimum dimensions.

- Bore Diameter (D) – Maximum and minimum dimensions.

- Socket wall thickness – (C) – Average of Socket wall thickness.

- Dimensional tolerances center to bottom of socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2½ to NPS 4 = +/- 2.5 mm

Types of Forged 90° Socket weld Elbow by class, size and wall thickness :

| Description | Class Designation | ||

|---|---|---|---|

| 3000 | 6000 | 9000 | |

| Elbows 45 and 90 degrees, Tees, Crosses, Couplings, Half-Couplings, End or Pipe Caps | ½ – 4 | ½ – 2 | ½ – 2 |

| ½ – 4 | ½ – 2 | ½ – 2 | |

| ½ – 4 | ½ – 2 | ½ – 2 | |

| Pipe Size by Wall Thickness | SCH 80 & XS | SCH 160 | XXS |

Types of Socket Weld Fittings :

Type Of Socket Weld Fittings Available At Best Price

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

Forged Fitting Type

Forged Fitting Standard

Forged Fitting Material

Forged Fitting Dimension

|

Forged 90° Socket weld Elbow Project Reference List

| PROJECT NAME / CUSTOMER | Riton Metal Industries | GRADES | LOCATION | YEAR |

|---|---|---|---|---|

| GAS AND CONDENSATE EXPORT SYSTEM | Forged 90° Socket weld Elbow AND BRANCH OUTLETS BW – SW | A182 F316L – A182F44 A182 F44 , A312S31254, A182 F316L, A105.N, A105 HDG, A350 LF2, A106 Gr.B, A106 Gr.B HDG , A333 Gr.6, A234 WPB | KUWAIT | 2015 |

| GAS DEVELOPMENT PROJECT | Forged 90° Socket weld Elbow, BRANCH OUTLETS | INCOLOY 825 | INDONESIA | 2015 |

| INDORAMA | Forged 90° Socket weld Elbow AND BRANCH OUTLETS BW – SW – THRD | A105 – A350 LF2 – A106B- A333 GR6 – A234 WPB – A420 WPL6 – A182 F304L | THE NETHERLANDS | 2015 |

| QUALITY STAMP TRADING -SAUDI ARAMCO | Forged 90° Socket weld Elbow , BRANCH OUTLETS SW | A105, A105 GALV, A350 LF2, A182F304L, A182F316L, A403 WP316L, A182F321, A182F44, A182F5, CU90/10 UNS C70610 | SAUDI ARABIA | 2014-2015 |

| REFINERY OFF GAS PROJECT | Forged 90° Socket weld Elbow, BRANCH OUTLETS BW-THRD, NIP OUTLETS | A105, A105 HDG A350 LF2, A182 F304/ 304L, A182F316/316L, A182F11, A105N, A106B, A234WPB, A333 | BELGIUM | 2014-2015 |

| MA’ADEN WA’AD AL SHAMAL PHOSPHATE | Forged 90° Socket weld Elbow AND BRANCH OUTLETS SW-BW | A350LF2, F304L, F316L, F904L, A182F60, ALLOY20 A105N, A106B, A234WPB, | SAUDI ARABIA | 2014-2015 |

| OIL AND GAS INC | Forged 90° Socket weld Elbow AND BRANCH OUTLETS BW | UNS NO 6625 | BRAZIL | 2014 |

| SHIDDIRGANG PROJECT | Forged 90° Socket weld Elbow, BRANCH OUTLETS BW-SW-THRD | BANGLADESH | 2014 | |

| SAUDI ARABIAN MINING COMPANY | Forged 90° Socket weld Elbow AND BRANCH OUTLETS SW – BW | A105, A105 GALV, A350LF2A182F304L, A182F316L | SAUDI ARABIA | 2014 |

| GAS TURBINE POWER PLANT PROJECT | Forged 90° Socket weld Elbow AND BRANCH OUTLETS SW | A105, A182F316L | IRAQ | 2014 |

| GRUPO CUNADO | FORGED STEEL FITTINGS | A105,A182F304L, A182F316L,F321, | TURKEY | 2013-2014 |

| ALSTOM | FORGED STEEL FITTINGS AND BRANCH OUTLETS | A105, A182F304L, A182F316L | MOROCCO, SOUTH AFRICA | 2010 |

| NORTH WEST REDWATER | Forged 90° Socket weld Elbow SW & NPT | A350LF2,A420WPL6, A182F304L-F316L,WP304L,HAST,C276 | CANADA | 2014-2015 |

| CANADA NWR PROJECT | Forged 90° Socket weld Elbow , BRANCH OUTLETS SW & NPT | F304L/316L/317L/347H/321H F11/F22/ UNS08825 | CANADA | 2014-2015 |

| DENIZ 2 PROJECT | Forged 90° Socket weld Elbow SW & NPT | A 105, A105 GALVA, A350LF2, A333 Gr6, A234WPB-A420WPL6, F304L, WP304L | AZERBAIJAN | 2014 |

| ADMA OPCO ABU DHABI | Forged 90° Socket weld Elbow, BRANCH OUTLETS BW-THRD, LATERAL, OUTLETS | A694 F52, A182F321, A182F316, A105.N, A312TP316L, A312 TP321, A182 F53 SUPER DUPLEX | UAE | 2014 |

| SAUDI ARAMCO HOLLAND | Forged 90° Socket weld Elbow | CuNi 9010 | SAUDI ARABIA | 2014 |

| MISSAN OIL Comp.PETROCHINA IRAQ | API COUPLINGS | L80 | IRAQ | 2014 |

| SAUDI ARAMCO | Forged 90° Socket weld Elbow, BRANCH OUTLETS BW-SW-THRD | MONEL 400, A182 F5, A182F316L, A182F304L, A105 | SAUDI ARABIA | 2014 |

We have supplied Forged 90° Socket weld Elbow to below countries

| Malaysia | Angola | Netherlands |

| Nigeria | Gabon | Iran |

| Egypt | Germany | Iraq |

| South Africa | Turkey | United Arab Emirates |

| Tanzania | France | israel |

| Kenya | United Kingdom | Jordan |

| Algeria | Italy | Oman |

| Uganda | Philippines | Kuwait |

| Ghana | Singapore | Qatar |

| Mozambique | Sri Lanka | China |

| Morocco | Thailand | Indonesia |

| Saudi Arabia | Vietnam | Japan |

| Canada | United States | Pakistan |

| Mexico |

Socket Weld Fittings

Socket Weld Fittings